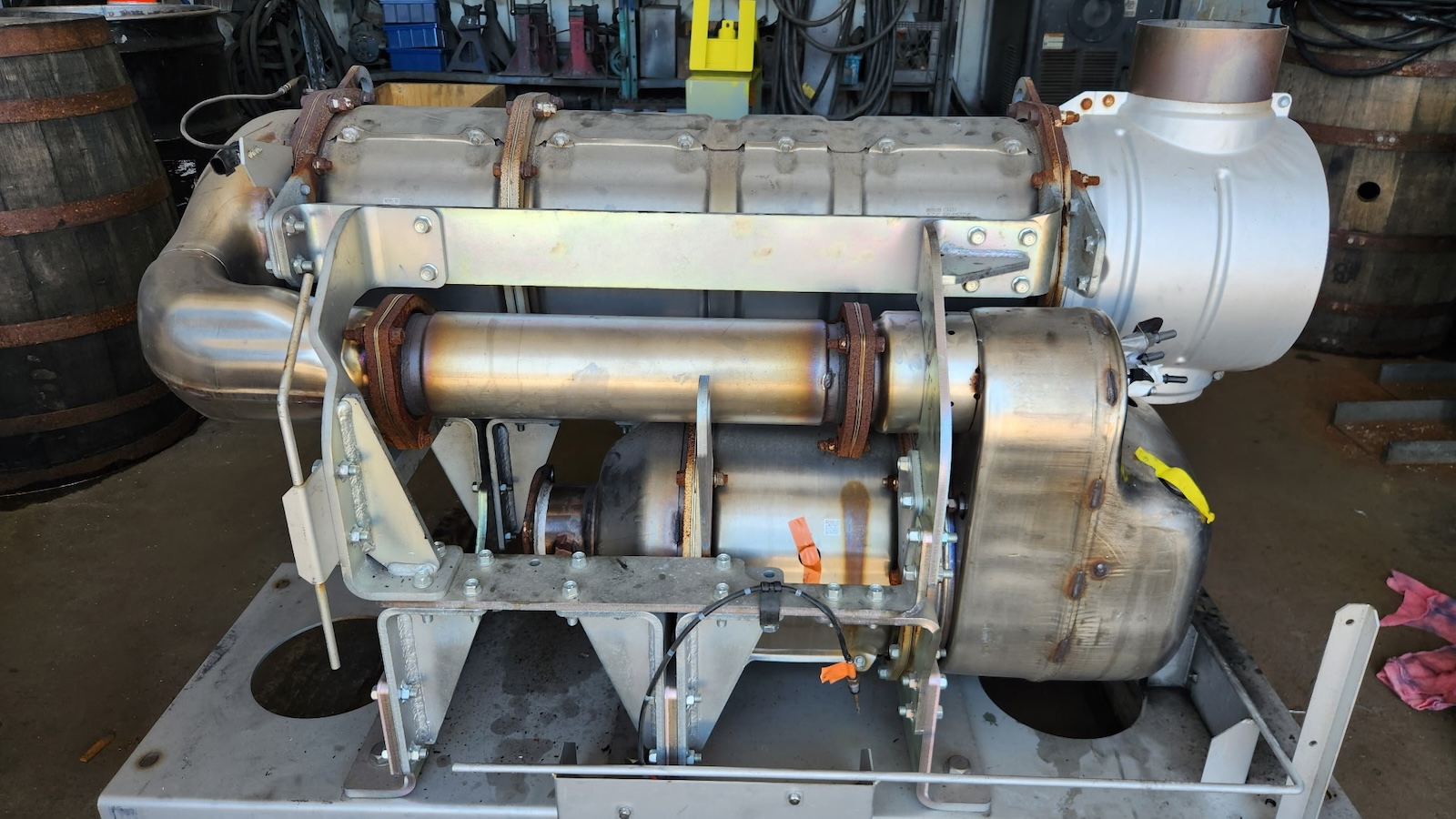

Facility managers overseeing backup energy programs perceive that diesel mills are very important for operational continuity. Nevertheless, trendy emissions laws and environmental priorities imply that Diesel Particulate Filters (DPFs) have gotten customary on many generator units, even in non‑cell functions. Correctly managing DPFs is essential—not only for emissions compliance, however for reliability, value management, and tools longevity.

This text presents 4 key methods tailor-made for facility managers: (1) Efficient Regeneration Scheduling, (2) Monitoring and Diagnostics, (3) Upkeep and Cleaning Protocols, and (4) Regulatory Compliance & Gas Practices. Every part gives sensible, in‑depth steerage on guaranteeing your generator’s DPF stays useful, compliant, and environment friendly—all backed by authoritative sources.

By following these methods, facility managers can proactively forestall downtime attributable to clogged DPFs, keep away from expensive fines beneath EPA or CARB laws, and prolong the operational lifespan of their generator programs. Let’s dive into every technique with readability and confidence.

1. Efficient Regeneration Scheduling

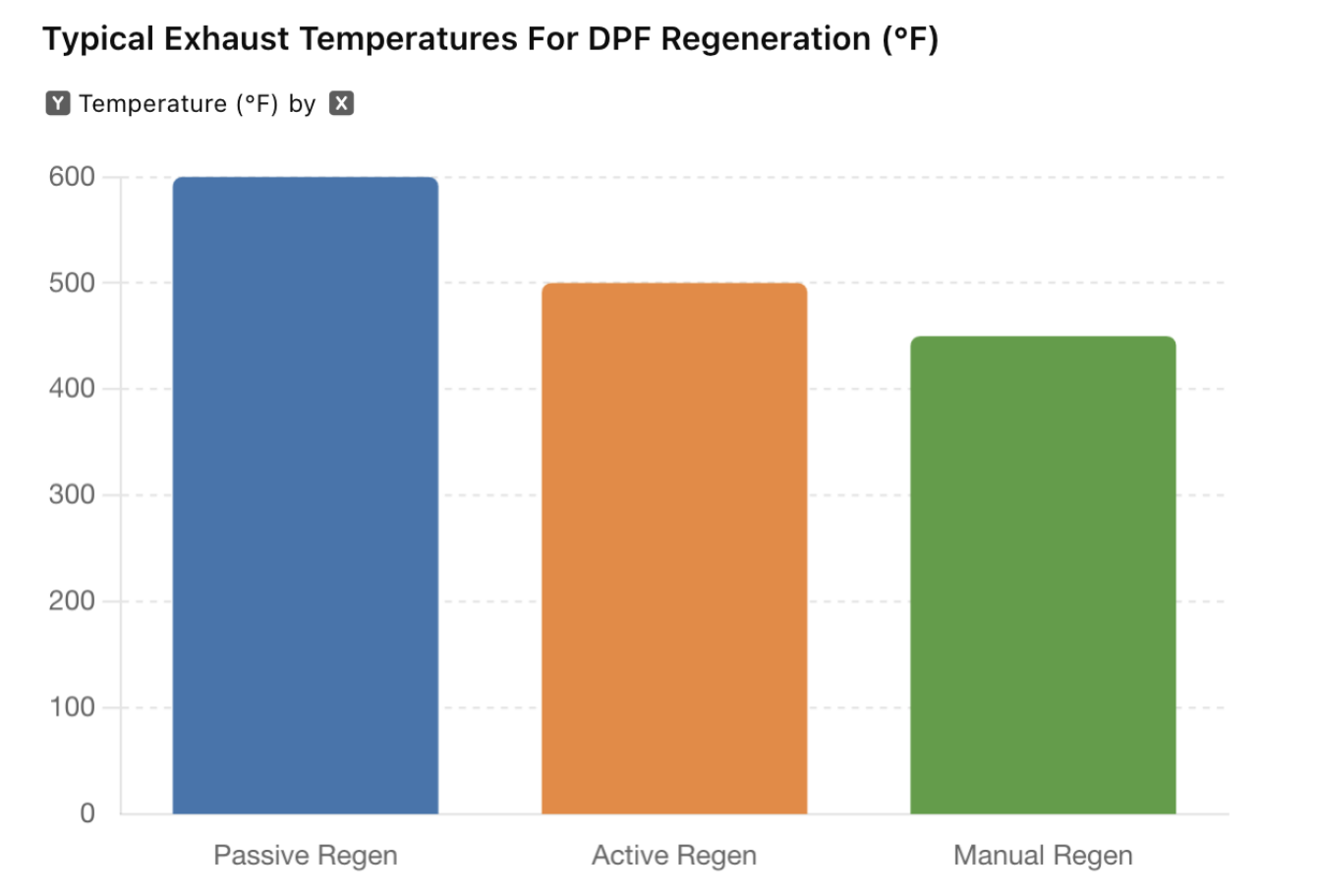

Correct regeneration of the DPF is the muse of dependable operation. Diesel particulate filters entice soot and particulate matter, which should be periodically burned off—a course of generally known as regeneration—to keep away from clogging and extreme again strain. There are two main varieties: passive regeneration, the place exhaust warmth naturally burns off the soot throughout high-load operation, and energetic regeneration, the place the system intentionally heats the DPF through gas injection or electrical heating when temperatures are inadequate.

Facility environments pose particular challenges. Mills on gentle or intermittent hundreds usually don’t attain the required 450–700 °F (≈230–370 °C) exhaust temperatures wanted for passive regeneration. Lively regeneration requires deliberate high-heat cycles—similar to load financial institution testing or scheduled high-output operation—to make sure soot burn-off.

Typical Exhaust Temperatures For DPF Regeneration

Facility managers ought to implement a regeneration schedule that features common load financial institution testing (e.g., month-to-month or quarterly), guaranteeing the generator reaches acceptable temperatures. This avoids passive regeneration failure and prevents points like DPF alarms, derating, or shutdowns. In circumstances the place passive regeneration constantly fails, handbook or pressured regeneration (utilizing diagnostic instruments to provoke a cleansing cycle) could also be obligatory (Snap-on).

- Schedule month-to-month load financial institution exams to make sure the generator reaches regen temps.

- Monitor whether or not regenerations full efficiently.

- Keep away from frequent “gentle load” operation (generally known as moist stacking).

- Associate with service suppliers for pressured regen when passive/energetic cycles fail.

By proactively scheduling regeneration—relatively than reacting to clogged filters—facility managers can preserve generator reliability, reduce service disruptions, and optimize gas utilization even in low-load functions.

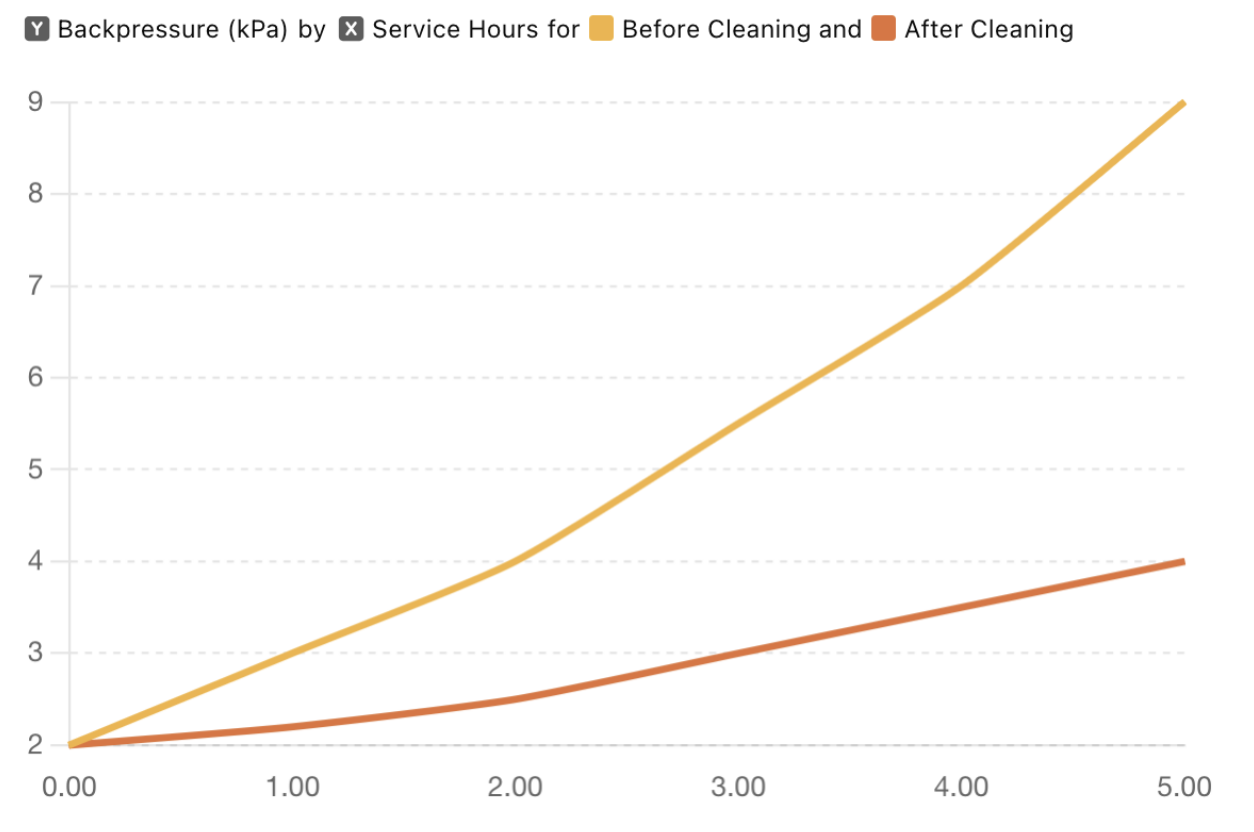

2. Monitoring and Diagnostics

Sustaining DPF well being requires real-time perception into filter situation. Fashionable generator programs usually embrace back-pressure and temperature sensors upstream and downstream of the diesel particulate filter. These allow the management system to detect when soot buildup calls for regeneration.

Facility managers ought to prepare for normal monitoring. Information logging of exhaust temperatures, differential strain, and cargo cycles must be retained—this documentation helps proactive upkeep and compliance (rypos.com). Monitoring developments over time helps predict DPF efficiency and anticipate points earlier than they escalate.

If the system flags excessive again strain, diminished runtime, or repeated regeneration failures, that alerts a necessity for intervention—similar to cleansing, sensor recalibration, or handbook regeneration initiation. Early detection prevents pressured regenerations, which are sometimes expensive and time-consuming.

“There are some [filters] that it’s important to pull out and change each 20 begins. There are some that it’s important to do yearly. It simply depends upon the tools producer.”

— Johnny Bradford

Briefly, monitoring will not be optionally available—it’s a vital technique. Facility managers ought to guarantee logging is enabled, distant monitoring programs are useful, and repair suppliers present common diagnostic stories. This enables well timed interventions and higher planning for DPF upkeep.

DPF Backpressure Over Service Hours

Sensors upstream and downstream of the DPF measure temperature and strain, alerting operators when soot ranges rise. Facility managers ought to leverage this information proactively.

- Monitor back-pressure alarms and examine early.

- Save information logs to doc efficiency and predict points.

- Use distant monitoring instruments the place accessible for quicker alerts.

- Calibrate sensors throughout scheduled generator service.

This proactive monitoring prevents emergency shutdowns and expensive downtime.

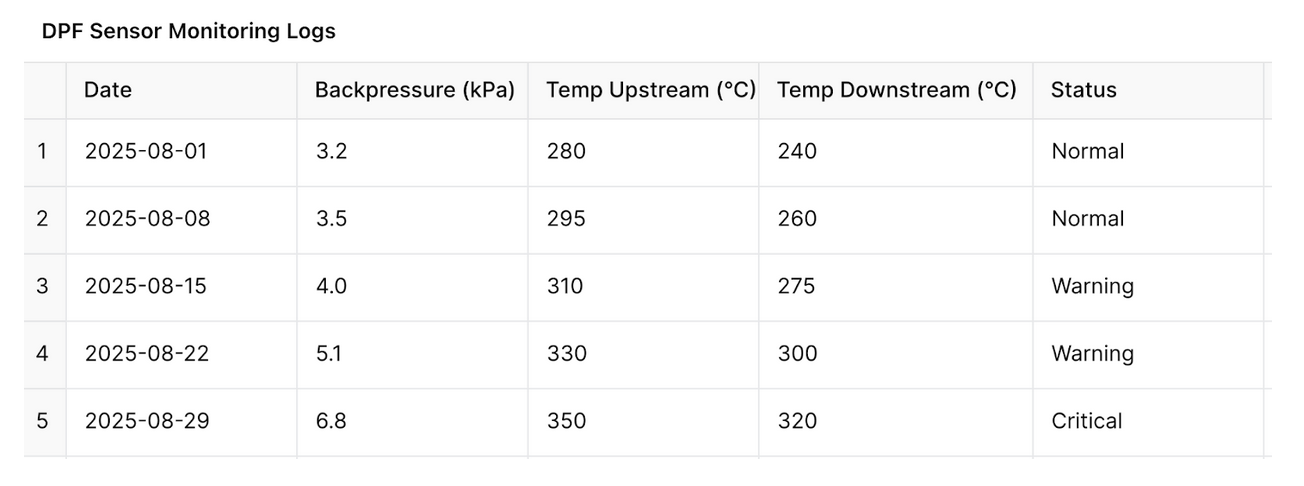

3. Upkeep and Cleansing Protocols

Even with efficient regeneration and monitoring, periodic cleansing or substitute of the diesel particulate filter is critical to take away gathered ash and non-regenerable residues. Engine oil consumption, gas components, or turbocharger failure can contaminate the filter, degrading its efficiency over time.

DPF Sensor Monitoring Logs

The method ought to embrace:

- Scheduled skilled cleanings, sometimes each 3,000–5,000 operational hours (topic to obligation cycle and atmosphere).

- Utilizing authorised strategies—thermal cleansing, pneumatic blasting, or aqueous cleansing—relying on filter sort. Improper strategies can injury the substrate.

- Contemplating the filter materials: cordierite is widespread and cheaper however has decrease thermal tolerance; silicon carbide (SiC) withstands increased temperatures and is extra sturdy, making it higher for heavy-use or high-temperature mills.

Facility managers ought to companion with certified service suppliers who use CARB- or EPA-verified diesel particulate filter applied sciences and cling to correct cleansing protocols. This minimizes the danger of substitute value, filter injury, and surprising downtime.

4. Regulatory Compliance & Gas Practices

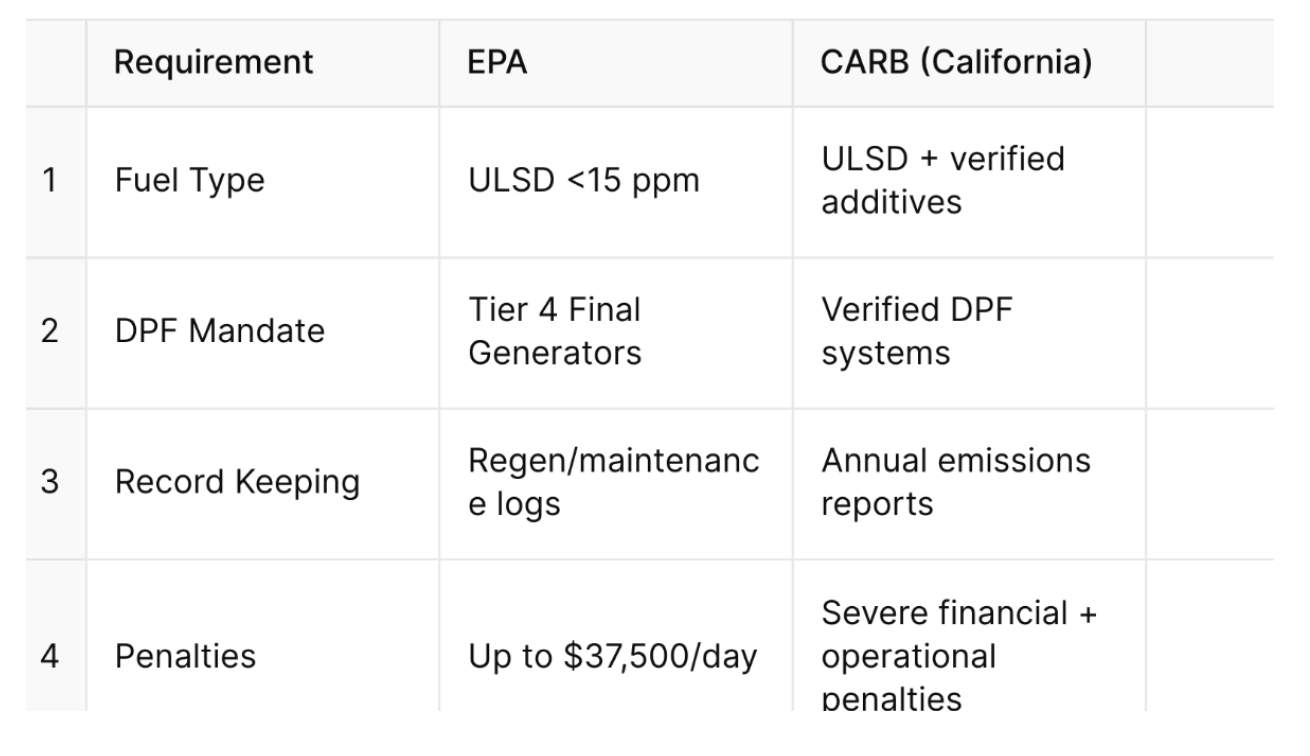

Compliance with EPA and CARB laws is crucial. Tampering with or eradicating DPFs is unlawful and may result in steep penalties beneath the Clear Air Act (AQMD). California, for instance, mandates CARB-verified particulate filters and strong upkeep practices to take care of compliance (California Air Resources Board, AQMD).

Use of correct gas can be essential. DPF programs require Extremely-Low Sulfur Diesel (ULSD) (<15 ppm sulfur) to operate successfully and keep away from untimely clogging or catalyst injury (rypos.com). Some areas might settle for higher-sulfur fuels provided that sulfur-tolerant diesel particulate filter programs are used—however verifying gas high quality is a key step in compliance and efficiency.

Compliance Necessities Comparability

Facility managers ought to doc gas sources, DPF upkeep logs, and regenerative cycles—each for inside evaluation and regulatory audits. Partaking service suppliers that perceive federal and native guidelines ensures that your generator system stays compliant and resilient.

Non-compliance with emissions guidelines can value tens of 1000’s in fines. Facility managers should perceive native and federal necessities.

- At all times use ULSD gas; confirm your provider’s high quality.

- Maintain emissions logs for inspections.

- Work with a CARB/EPA-verified service supplier.

- Prepare workers on the authorized and security penalties of bypassing DPFs.

—

For facility managers, optimizing generator DPFs is about greater than compliance—it’s about guaranteeing reliability when energy issues most. The 4 methods—Regeneration Scheduling, Monitoring, Upkeep, and Compliance—type a complete roadmap to cut back threat, management prices, and prolong generator life.

By staying proactive with these generator diesel particulate filter optimization methods, facility managers can preserve their programs prepared, environment friendly, and compliant. For knowledgeable assist, Duthie Energy affords DPF inspections, cleanings, and compliance companies to assist amenities keep forward of the curve. Click on here for a quote.

Trending Merchandise